Average Age of Inventory

A measure that represents the number of days it takes to sell the inventory

What Is the Average Age of Inventory?

The Average Age of Inventory is a measure that tells us how long, on average, it takes for a company to sell its inventory. It's an important metric in business because it helps assess how well a company manages its inventory and the risks it faces in the market.

When goods don't sell quickly or at their full retail price, they become what's called "aging inventory". Despite being a reasonably simple computation, it examines management effectiveness and a company's exposure to market risk.

Retailers monitor their aging inventory because as an item spends too much time (6 months and more) in store, it requires a markdown for obsolescence potential.

Generally, a brand's potential for profitability increases with the rate at which its inventory is sold. Therefore, to identify inventory inefficiency and/or lost earnings, calculating the average inventory age is a crucial component of inventory management while giving the company a clear idea of profitability potential.

One should take into account the average inventory cost, cost of goods sold (COGS), and inventory turnover ratio to calculate the inventory age for product listings (ITR)

Assessing a store's exposure to market risk can be done by looking at the average age of its inventory. A store that takes too long to sell an item has to write off the article as obsolete after a few months or lower the price, which would result in a loss of revenue.

However, it is crucial to remember that this risk evaluation approach only functions when comparing two stores of the same type. And by the same type, we mean it could be the same size or similar industry.

Key Takeaways

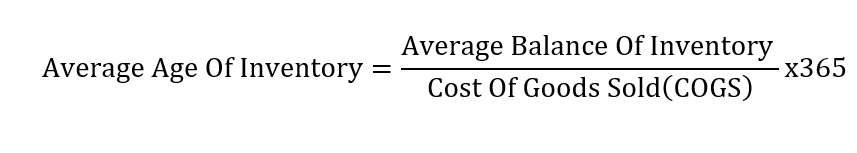

- The average age of inventory is a metric used to assess how long it takes for a company to sell its inventory. It is calculated by dividing the average inventory balance by the cost of goods sold (COGS) and then multiplying by 365 to get the number of days it takes to sell the inventory.

- This metric is important because it provides insights into a company's efficiency in managing its inventory. A lower number of days indicates faster inventory turnover, which can lead to higher profits as it brings cash back into the business more quickly.

- A high average age of inventory suggests poor inventory management and can lead to reduced profitability. When inventory sits on the shelves for extended periods, it ties up capital that could be invested elsewhere and can result in lower sales and revenues.

- The average age of inventory can be used to compare different companies in the same industry. Companies with lower average ages are generally more efficient at managing their inventory and may be better investments.

- Inventory management involves broader strategies and planning for maintaining appropriate inventory levels, while inventory control focuses on day-to-day tracking and management of current inventory. Both are crucial for effective operations.

What is inventory?

The accounting of goods, components, and raw materials that a business sells or utilizes in production is known as inventory. Inventory management is used by business leaders to make sure they have enough goods on hand and to spot when there is a shortfall.

The action of counting or listing objects is referred to as "taking an inventory." All stock in the various manufacturing stages is referred to as inventory, which is a current asset in accounting terms. The list is maintained by businesses to ensure production and sales efficiency.

For most businesses, inventory is a significant asset on the balance sheet. Nevertheless, having too much inventory can be a problem for businesses.

Inventory, often referred to as the stage between production and order fulfillment, is essential to all aspects of a company's operations because it is frequently the primary source of income.

Even though inventory can be categorized and characterized in various ways, management ultimately impacts an organization's ability to fulfill orders.

An essential part of the inventory is available information. Businesses gather important info and statistics, for instance, by keeping track of raw materials, safety stock, finished goods, and even packing materials.

These insights influence a business's future purchase and fulfillment activities. For example, the rate at which companies replace their inventory and assign priority for repurchase depends on understanding consumer trends and sale rates.

Notable Types of Inventory

Inventories are any asset or resource that an organization purchases and holds with the intention of selling, uses to create finished goods that will be sold further, or uses as raw materials or consumable supplies to manufacture goods or provide services.

- Raw Materials

A corporation employs raw materials to assemble and finish its goods for distribution. The natural components are generally unrecognizable from the finished product when it is finished, such as the oil required to make shampoo. - Elements

In that they are the materials a corporation employs to build and finish items, elements are similar to raw materials. Nevertheless, unlike natural materials, recognized components such as a pin remain in the final product for distribution.

A male connector has pins as well that fit into female connectors. Sometimes a connector's description will refer to how many pins it has. - Work-in-progress (WIP)

Inventory is a term for produced items and includes labor, packing supplies, raw materials or componentry, and overhead. - Finished goods

These are products that are prepared for sale. - Goods for maintenance, repair, and operations (MRO)

MRO is inventory frequently presented as supplies, which help with the production of goods or the maintenance of businesses.

MRO's goal is to guarantee that the organization always has the equipment, parts, materials, and supplies required to maintain the company's assets in stock. However, MRO must also consider the cost and the amount of space needed to store the maintenance inventory.

1. Packing and Packaging Materials

There are three types of packing and packaging materials: primary, secondary, and tertiary.

The product is made usable and protected by the primary packaging. The finished product packaging, known as secondary packing, may contain labels or SKU details, while bulk packaging for transportation is tertiary packing.

2. Safety stock and anticipation stock

Safety and anticipation stocks are different types of inventory that businesses purchase and keep on hand in unforeseen circumstances.

Despite having carrying expenses, safety stock promotes customer satisfaction. Anticipation stock is similar, consisting of unfinished or finished goods that a company buys based on market and production trends.

A company might buy safety stock if the price of raw materials increases or the peak selling season is about to start.

What is Inventory management?

Inventory management refers to the control of non-capitalized assets, often known as inventory and stock goods. Inventory management controls the movement of products from producers to warehouses and from these locations to points of sale as a part of supply chain management.

The comprehensive tracking of every new or returned item entering or exiting a warehouse and/or point of sale is a crucial component of inventory management.

Helping a business to ensure that there is never an excess or lack of product on hand, inventory management is essential to a company's health because it lowers the danger of stockouts and inaccurate records.

To comply with Securities and Exchange Commission (SEC) standards and the Sarbanes-Oxley (SOX) Act, public corporations must keep track of their inventory with standards. To demonstrate compliance, businesses must document their inventory management procedures.

1. Why is inventory management critical?

Businesses can balance their input and output inventories by using effective inventory management. The more effectively a company manages its inventory, the more money it may save on operating costs.

Certain adverse circumstances of stock can harm businesses, such as having overstock. Overstock occurs when a company has too much inventory. Businesses with excess inventory have money locked up on the list, which restricts cash flow and may result in a budget deficit.

Deadstock, or overstocked merchandise that cannot be sold can frequently sit in storage and reduce a company's profit margin. This shows the efficiency that can be achieved with proper inventory management for businesses.

2. The inventory management process

In smaller businesses, as opposed to larger ones with more physical space, goods can move straight to the stock area rather than a reception spot. In addition, the items may be finished products rather than raw materials or components if the company is a wholesale distributor.

After that, unfinished goods are taken out of the storage rooms and transported to the production facilities, where they are transformed into finished goods.

The final products can be dispatched directly to clients or returned to the stock areas where they were kept before being shipped.

Factors such as lot numbers, serial numbers, cost of goods, number of goods, and dates, when they move through the process are just a few of the statistics that inventory management employs to keep track of products.

When a company receives a client order and continues until it is shipped, they produce on demand. If not, the process starts when a business forecasts demand and then places orders for the necessary components or raw materials.

Analyzing sales patterns and planning the organization of product storage in warehouses are additional steps in the inventory management process.

Inventory management techniques

Inventory management controls the complete flow of goods, from purchase to sale, ensuring that you always have the necessary quantities of the appropriate item at the right location at the right moment.

1. Stock Review

Stock review is the most simple inventory management strategy, and smaller organizations tend to find it more appealing. Regular stock reviews involve comparing current stock levels to anticipated demand.

Although automated stock reviews can be used to determine minimum stock levels, most of the work is still done manually. This allows for regular inventory inspections and the reordering of goods to meet the minimum levels.

2. Just-in-time (JIT) methodology

JIT is based on an analysis of consumer behavior, in which things are delivered to customers in the sequence in which they are ordered.

This strategy examines purchasing habits, seasonal demand, and location-based characteristics to determine which commodities are required at particular times and locations.

The benefit of JIT is that it allows for immediate fulfillment of consumer demand without the need for significant stock amounts of goods.

3. ABC analysis methodology

ABC analysis divides stock into three groups based on the items' cost relevance and inventory values.

High-value, low-quantity items are represented by Category A, moderate-value, moderate-quantity goods are characterized by category B, and low-value, high-quantity interests are represented by Category C.

4. Economic order quantity (EOQ) methodology

As a result, expenditures are reduced, and money that would otherwise be locked up in excess inventory is made available.

An inventory management strategy called economic order quantity aids in the formulation of effective inventory management choices. It refers to the ideal quantity of inventory a business should buy to meet demand while lowering holding and storage costs.

Spending is decreased as a result, and money that would have been kept in surplus inventory is now available.

1. First in, first out (FIFO) methodology

FIFO methodology suggests that the oldest stock is sold first to keep current with demand. This approach is particularly crucial for companies dealing with foodstuffs that must be sold quickly to avoid waste.

2. Last-in, first-out (LIFO) methodology

LIFO methodology suggests that sales are usually recorded, starting with the newest product. This is a sensible approach when inflation is a concern and prices rise.

Selling the newest inventory before older inventory results in lesser profitability and less taxable income because it has the highest cost of production. LIFO also means that merchandise is reported at a lower price than older goods still on the shelves.

What is the average age of the inventory ratio?

According to Accelerated Analytics, the average days of inventory ratio demonstrates the typical number of days it takes a business to turn its inventory around in a specific time frame, often a year.

A low number indicates that a business can increase its revenue since it quickly sells its inventory.

However, the high average age of inventory is a sign of poor management and inefficient capital usage.

According to Chron, the average inventory age represents the days it takes to sell a stock. Therefore, one must first determine the average inventory balance over a specified period to determine the average list age.

After that, divide the outcome by the cost of products sold (COGS). Finally, the number of days a year is multiplied by the result as the last step in determining this ratio (365).

- Cost of goods sold = Starting inventory minus ending inventory plus further purchases.

- The average inventory balance is calculated by dividing the total of the beginning and ending inventories by 2 (in a year).

Why is the Average age of Inventory important?

To recoup the money invested in inventories, businesses must sell them (list) for gains. Because of this, the average stock age reveals how effectively a company recoups and utilizes its resources.

A smaller number of days signifies effective inventory turnover for a business. Quick inventory turnover boosts profits by bringing money back into the business. Higher ratios indicate better asset management and utilization by firms.

On the other hand, lower performance is linked to a greater average age of inventory. A corporation makes fewer sales the longer it maintains its inventory. Fewer sales significantly decrease revenues and pose a concern for businesses.

Additionally, businesses in the same sector can be compared using this ratio. For example, a company that turns its inventory more quickly is more likely to generate greater profits, making it a better investment.

Inventory Management vs. Inventory Control

Inventory management and control both keep close track of supplies. Inventory management includes control functions, which monitor daily trends for each item. Over more extended periods, inventory management follows more general tendencies.

Inventory Control is more specified and accurate; however, inventory management considers the general rules to manage and follow.

For exact, real-time updates, both methods use mobile devices to scan barcodes and do radio frequency identification (RFID) scans.

- Inventory management and control are necessary for effective direct sales and channel operations.

- Inventory control includes the procedures and equipment required to keep track of current inventory, whereas inventory management refers to the entire plan to ensure an appropriate list.

- Businesses may use an inventory control system alone, although doing so would be advantageous.

Some experts believe that effective stock control is the first step to successful stock management. Therefore, it is advised to start by identifying the stock types in their warehouse and their corresponding condition.

Many physical and online retailers don't manage their warehouses. Although they might have their backrooms, most of their merchandise is kept in a warehouse that they either rent or lease.

Third-party transportation providers ship the products to either customers or retail stores to complete orders.

Amazon is not concerned about not having warehouses in its possession because most of the products that Amazon sells on its platform and, increasingly, the products that other companies sell on it are stored by Amazon. In other words, the corporation has massive space under its management.

Amazon held 288 million square feet of space, including warehouse space, as of 2018. North America makes up two-thirds of this property's footprint.

or Want to Sign up with your social account?